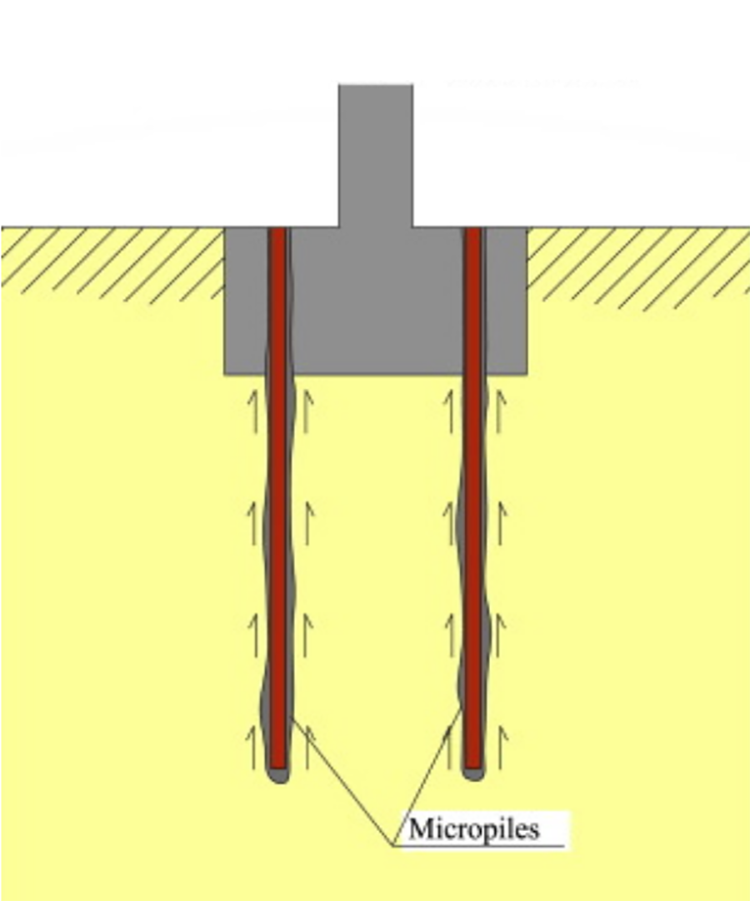

Micropile Foundation and Installation Contractors in Central Florida - Micropiles are sometimes called mini piles, are used in locations that usually have limited access. These piles can carry a very high weight capacity despite their small diameter. Micropiles can be identified by having a diameter of 300mm or less. They are reinforced with steel and carry their weight atop a steel platform, which distributes that load evenly among the other mini piles.

What is a Micropile

What is a Microppile - Micropile is becoming a much more common groundwork solution when foundation depths exceed 8' to 10'. Micro-piling provides a more effective, practical, and eco-friendly option for foundation installation and repair. Another reason micro-pilling is becoming the best solution is because it requires minimal excavation and the materials used are safer. Traditionally, deep strip foundations require excessive digging. This poses a strong risk for trench collapse and excessive use of materials

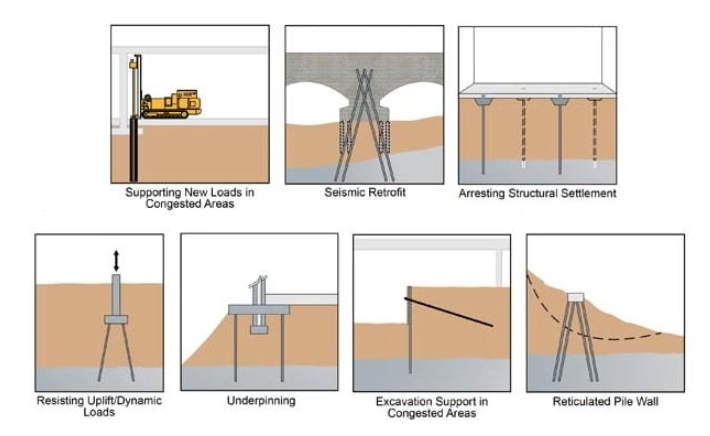

Micropile also known as minipiles are a deep foundation element made of shell casings, rebar and grout. They can reach extreme depths of 200 feet and can sustain work loads of hundreds of tons. Micropiles are usually used to replace, renovate or repair damaged foundation structures that have been affected by nearby construction, seismic retrofitting or in-situ reinforcement including embankment, slop and landslide stabilization.

Since its conception in the 1950s, the use of micropiles has been steadily increasing. Micropiles have been used mainly as elements for foundation support to resist static and seismic loading conditions. Many of these applications are suitable for transportation structures.

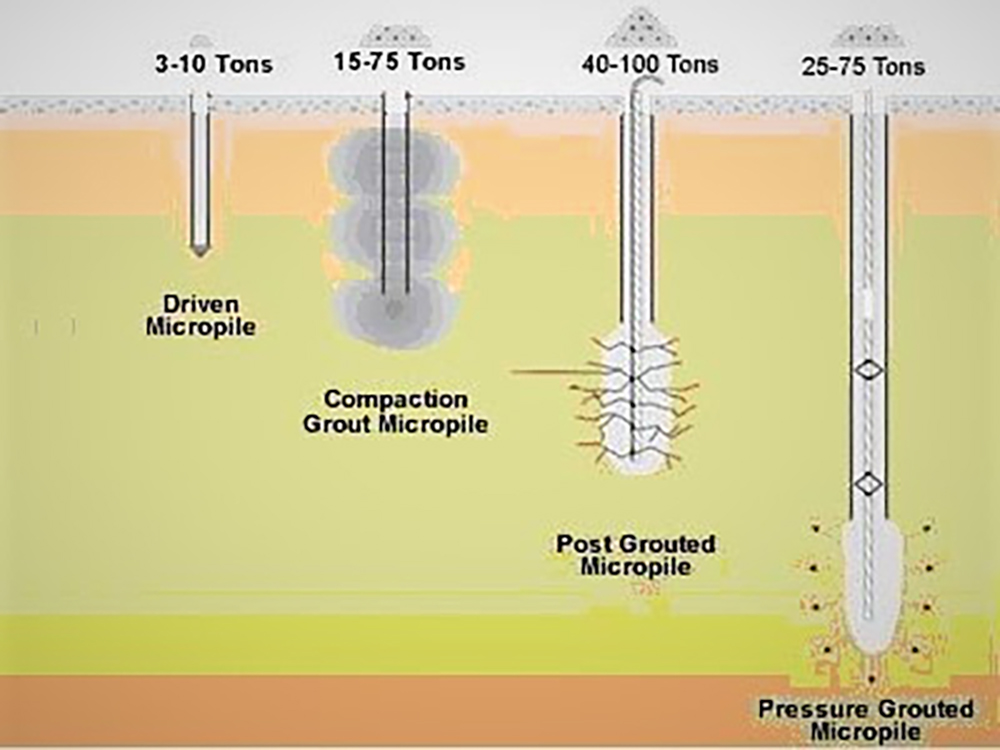

Types of Micropiles

A driven micropile is the typical mini pile used. It is a solid, metal tube driven into the ground with a pile cap on the end to help it penetrate the ground. It can be used in virtually any type of ground. It can hold 3-10 tons of weight.

Compaction grouting, also called low mobility grouting, reinforces unsuitable soils back in place. It also is used to fix sinking structures or to underpin existing foundations. The low mobility process displaces and compacts the surrounding soil and builds high-stiffness compaction grout columns.

The hollow bar micropile is named due to it being a micropile with a hollowed center. This pile requires no pre-drilling. As this pile is being drilled into the ground, a cement with a thin consistency is poured into the hollowed center until the pile reaches its desired depth.

Pressure grouted micropiles can be tailored to function for any specific project. It provides tension capacity to stabilize taller structures and added strength to carry heavier loads. Pressure grouted piles are typically drilled into soil, sand, or broken-up rock to develop a bond zone. The bond zone provides multiple structural additions including compression, tension and lateral loads.

Any Questions? Give Us A Call Today!

407- 481- 8383

Advantages of Micropiles For Your Home

Quick and Easy Installation - Since micropiling doesn’t require digging, less equipment and time is needed to complete your project. Time, noise and equipment size are all deciding factors for many property owners and with micropiling all of these are minimal. You will be able to have a stronger foundation than before, in little to no time and with little noise.

Cost-Effective - Micropiles provides the most in-expensive solution to repair your foundation or install a new one. Once completed, it is also durable.

Foundation Strength - Micro piling is done vertically and once the piles are secured in place, the foundation structure will be more stable and stronger.

Fender Marine Construction is able to offer you complete service from site clearing, foundation design by a structural engineer and getting the right permits needed. We will also bring in our management team, skilled and licensed craftsmen and high-quality equipment required for your project to be completed efficiently.

No matter the job, we will always provide professional services to our customers. We are here for our customers and will answer there calls no matter the time of the day, emergency or a minor job, we will be there. We will always put our customers first and give them what they deserve. We pride ourselves in being a company that will suit the customer’s needs. In the case of an emergency, we will make sure to respond in a timely manner.

Micropile Installation Services

Micropile Installation Services - A borehole with a diameter of 150 to 300 mm is pierced using a bentonite slurry by rotary boring tools to maintain the sides of the created opening. A liner of complete deepness up to acid rock/ strata is needed. M.S. or HDP pipeline linings are usually used. MS liners, however, are preferable. The reinforced steel cage of big size rebars is offered as heap support. A stack is grouted with an abundant grout of cement as well as fine sand with a water-cement proportion of 0.5. This grout also may have a minimum compressive strength of 480 kg/cm2 in 28 days.

Additionally, any other ideal approach including filling the bore with rugged aggregate up to a specified height of about 1m, as well as filling it subsequently with cement grout can also be suggested. The piles are socketed sufficiently into the hard strata/rock required to create the development which comes primarily from friction in the socket. The safe vertical load capacities are generally from 25 to 35 MT and lateral or shear capacities are generally from 2 to 4 MT.

Sequencing For Micropiles

The pile heaps should be installed in a specific sequence that the tons bring the capacity of the installed stack beforehand to remain the same. The series of loading shall be as per working illustrations. In a heap group, the sequence of installation of these heaps normally is from the center to the perimeter of the group. It can also be from one side that the dirt is limited to so that flowing out during procedures is prevented.

Serving Central Florida

Alafaya

Altamonte Springs

Apopka

Azalea Park

Belle Isle

Brandon

Brevard County

Casselberry

Clearwater

Clermont

Cocoa

Cocoa Beach

Daytona Beach

Debary

Deland

Deltona

Dr Phillips

Edgewater

Eustis

Fairview Shores

Geneva

Goldenrod

Inverness

Jacksonville

Killarney

Kissimmee

Lady Lake

Lake Buena Vista

Lake Butler

Lake County

Lake Mary

Lake Monroe

Lake Wales

Lakeland

Largo

Leesburg

Lockhart

Longwood

Maitland

Melbourne

Merritt Island

Mount Dora

New Port Richey

New Smyrna Beach

Oak Ridge

Ocoee

Orange City

Orange County

Orlando

Osceola County

Oviedo

Palm Bay

Palm Harbor

Pine Hills

Plant City

Port Orange

Riverview

Rockledge

Saint Cloud

Sanford

Seminole County

Sky Lake

St Petersburg

Tampa

The Villages

Titusville

Union Park

Volusia County

West Melbourne

Wesley Chapel

Windermere

Winter Garden

Winter Haven

Winter Park

Winter Springs

Zephyrhills